Designs & CAD

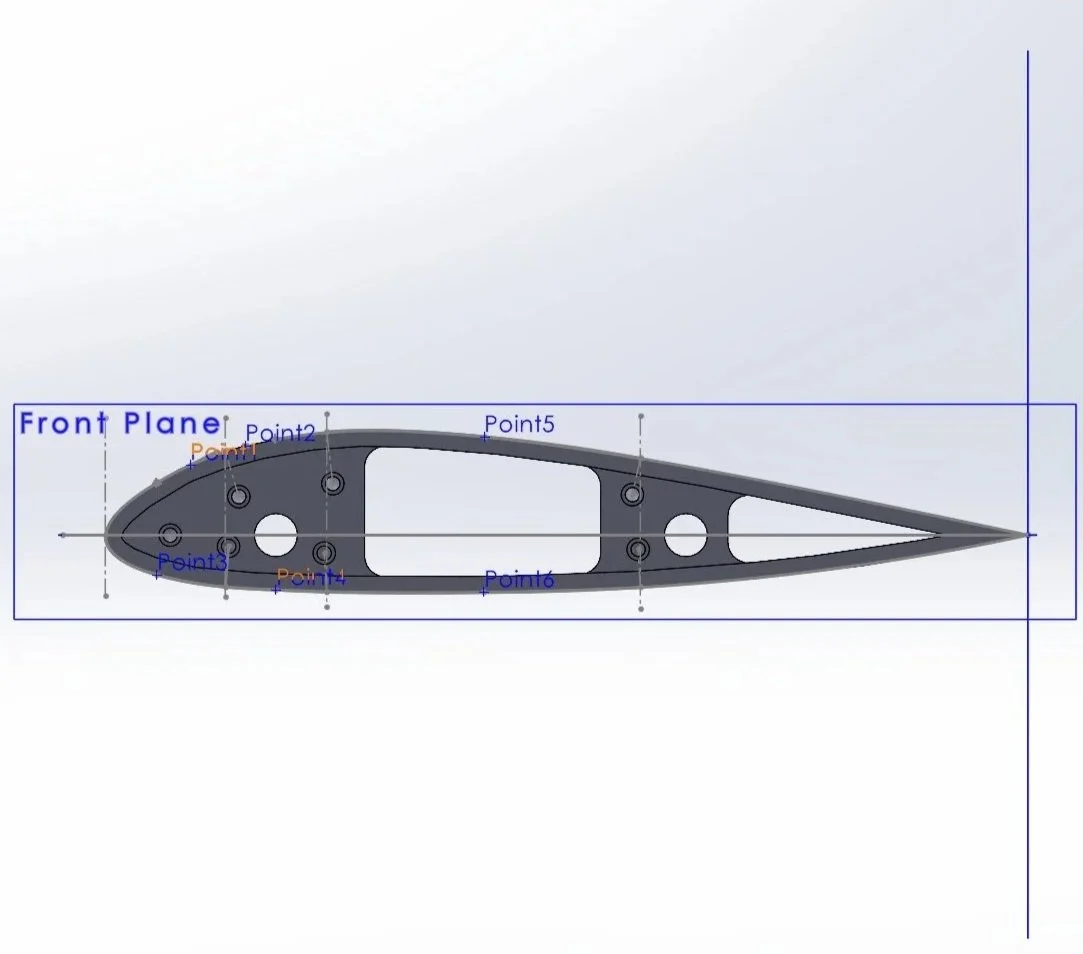

custom Airfoil

-

Challenge

• Design a unique airfoil geometry optimized for aerodynamic performance

• Model the airfoil in CAD with a 6-inch chord length for 3D printing

• Conduct wind tunnel testing using pressure measurements along the surface

• Evaluate lift and drag performance across multiple angles of attack to assess efficiency and stability

-

Approach

• Used a pitot-static tube to measure airspeed in the wind tunnel via total and static pressure differences

• Integrated pressure taps at the stagnation point and multiple locations on the upper and lower airfoil surfaces

• Connected each tap through the hub to a pressure sensor for data acquisition

• Applied a calibration equation to convert measured voltages into pressure values for analysis

-

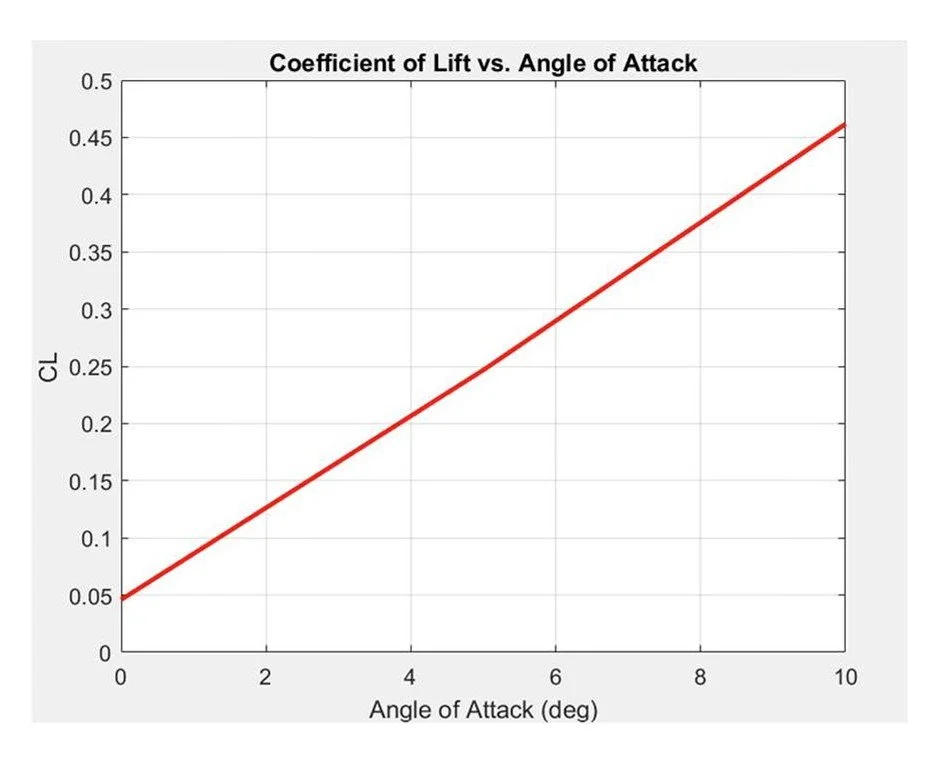

Solution

• Showed theory-consistent behavior for the coefficient of lift vs. angle of attack

• Displayed an approximately linear relationship from 0° to 10°, with a peak lift coefficient of 0.46

• Demonstrated a smooth increase in lift without premature stall behavior

• Confirmed a successful airfoil design with stable, reliable, and predictable lift performance within the tested range

Volt-veil

-

Challenge

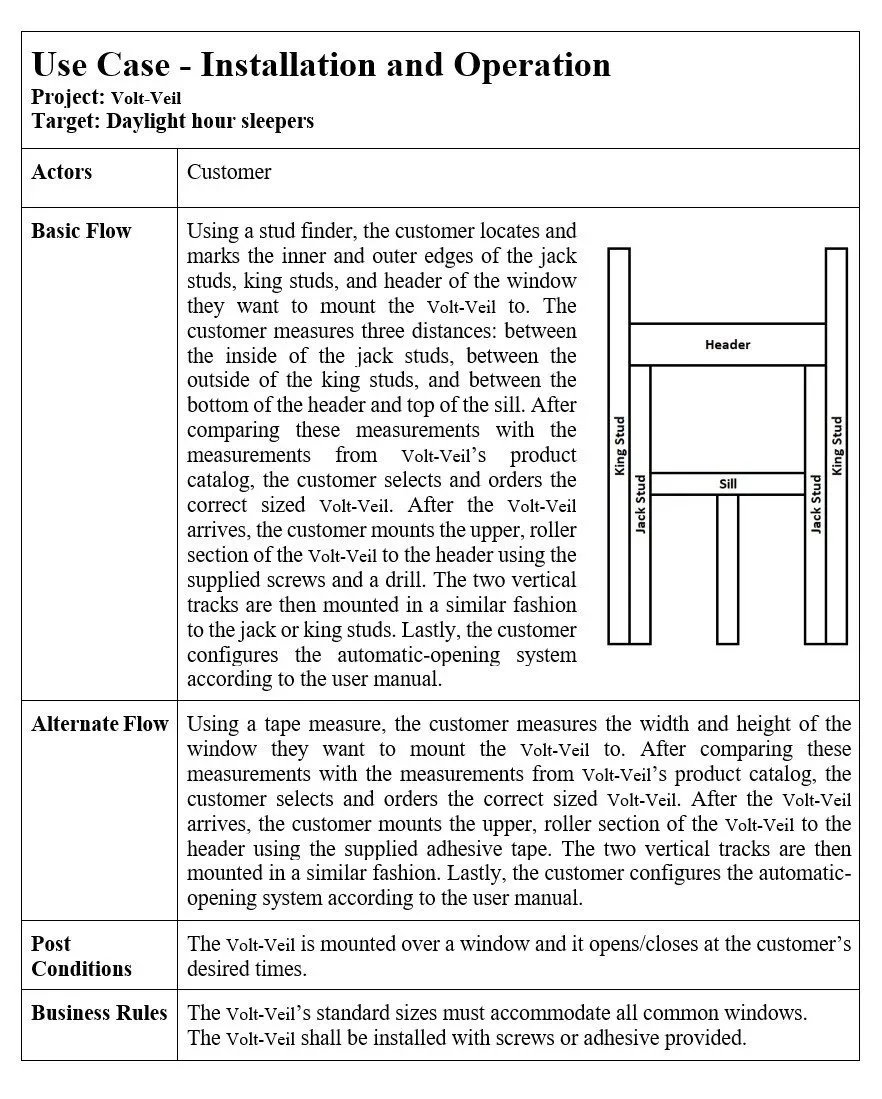

• Identify and evaluate market opportunities through brainstorming, weekly observations, and targeted questions to uncover unmet customer needs

• Apply design and feasibility criteria to narrow potential product ideas

• Select Volt-Veil, a zero light-bleed, automatic curtain system, for its large market potential and low competition

• Conduct market analysis through customer surveys to define the product’s mission, target users, and design requirements for successful development

-

Approach

• Planned and managed the project using structured tools such as a Gantt Chart, DSM Chart, and resource allocation table to define timelines, responsibilities, and dependencies

• Identified customer needs through surveys and analysis, translating them into measurable target specifications and a Quality Function Deployment (QFD) matrix

• Developed and evaluated design concepts using structured methods including concept generation, concept screening/scoring, and Failure Modes & Effects Analysis (FMEA) to select the most viable solution

-

Solution

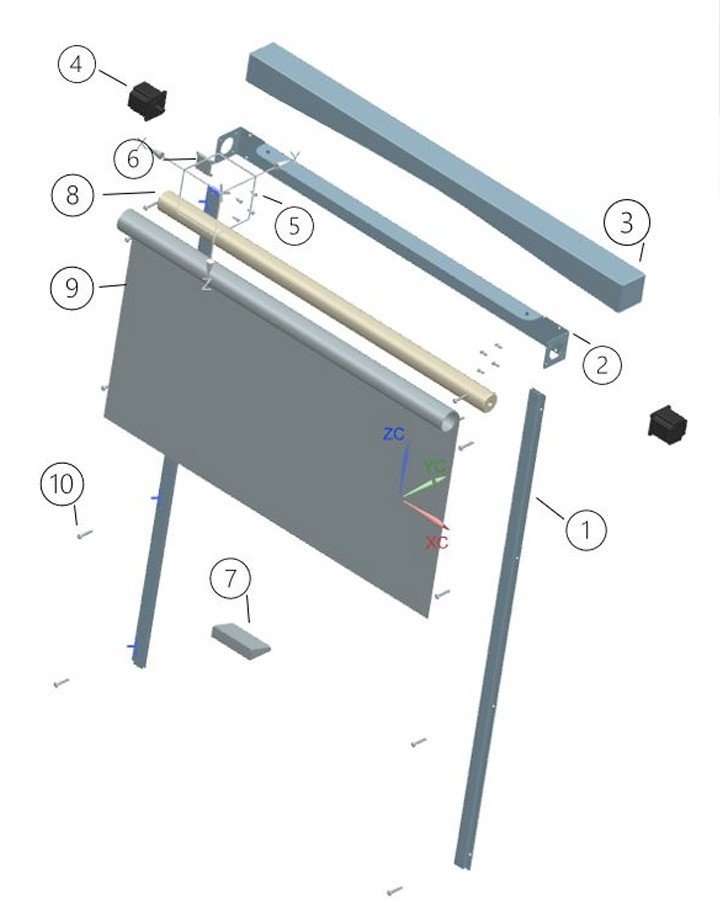

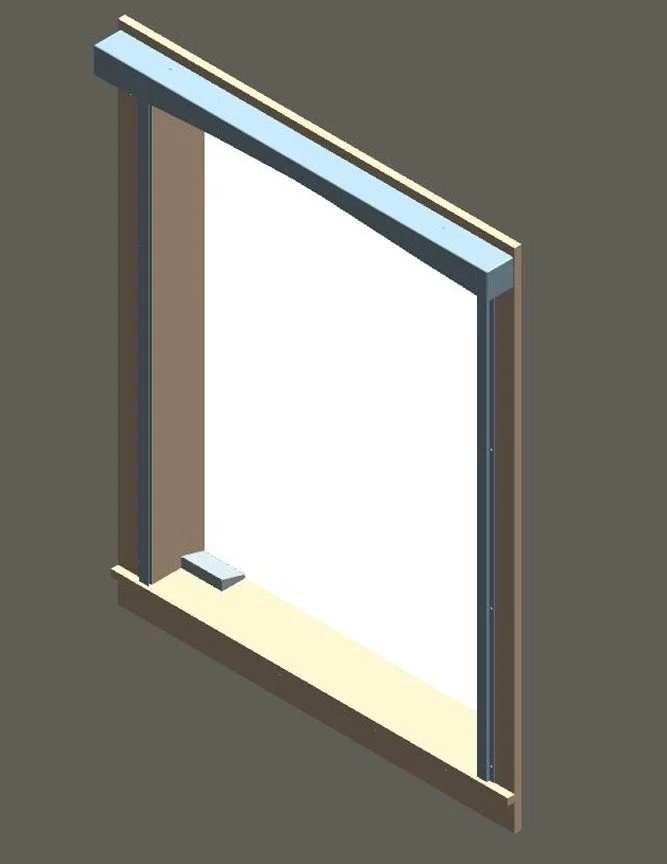

• Utilized CAD modeling to design, prototype, and refine the curtain’s mechanical and housing components for manufacturability

• Integrated a stepper motor, microcontroller, and programmable timer to enable automatic opening and closing based on user preferences

• Validated performance through assembly analysis, cost evaluation, and functional testing, confirming reliable operation and market feasibility

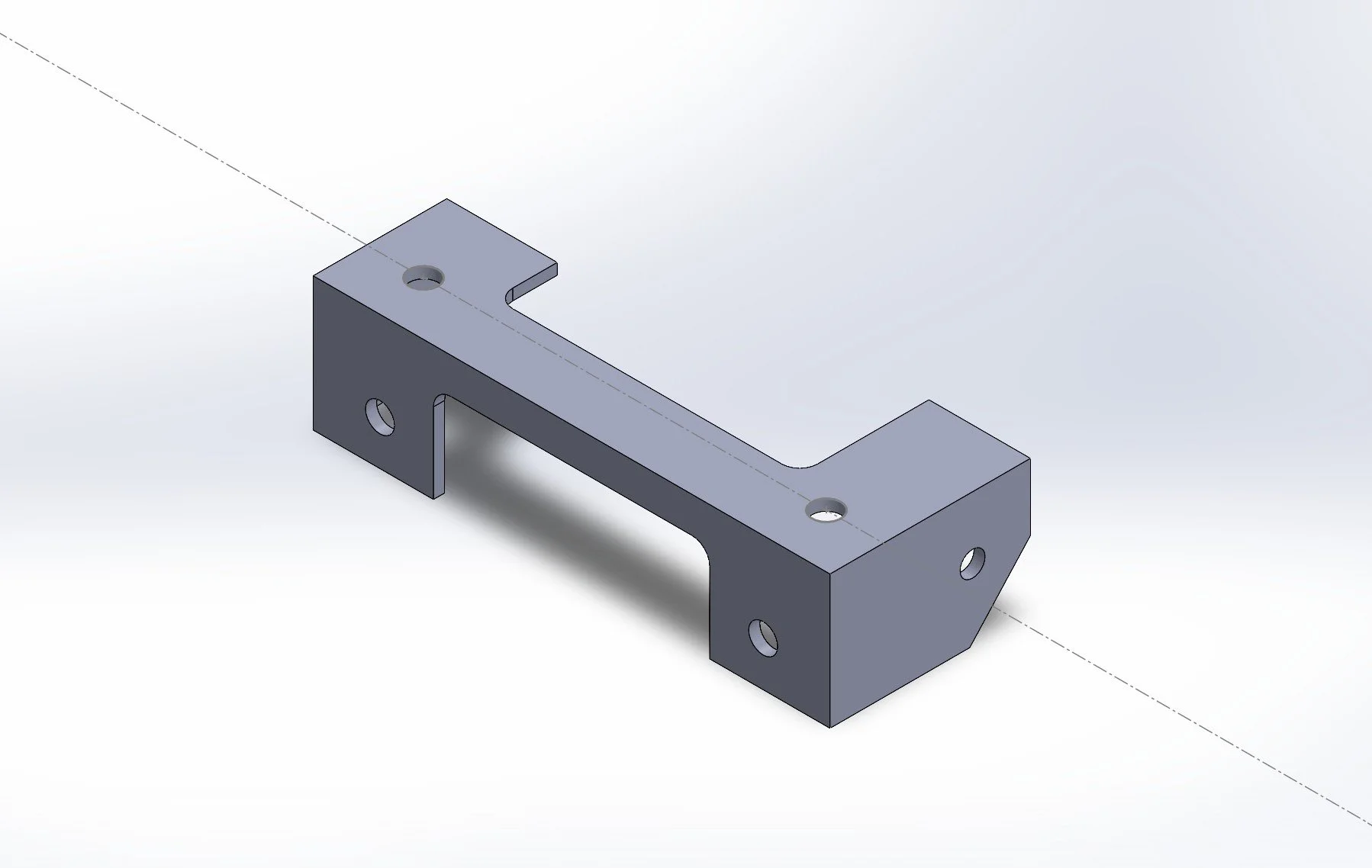

parking brake system

-

Challenge

• Must hold the fully loaded car on dry pavement against a 10% weight force without wheel chocks

• Operates independently from the main braking system and is excluded from main brake tests

• Must lock in place, be set from the seated, belted position in one motion, and stay engaged until intentionally released

• No tire or wheel-contact designs allowed—must fit within tight space constraint

-

Approach

• Used a pitot-static tube to measure airspeed in the wind tunnel via total and static pressure differences

• Integrated pressure taps at the stagnation point and multiple locations on the upper and lower airfoil surfaces

• Connected each tap through the hub to a pressure sensor for data acquisition

• Applied a calibration equation to convert measured voltages into pressure values for analysis

-

Solution

• Developed a parking brake system that fits within the vehicle’s tight space constraints and complies with all American Solar Challenge regulations

• Utilized a dedicated rear caliper mounted on the left rear wheel that is fully separate from the main braking system

• Featured a simple lever mechanism that locks securely in place and is easy to operate while fastened in the seat

• Successfully passed the 10% pull test, confirming that the brake can hold the fully loaded vehicle on dry pavement as required

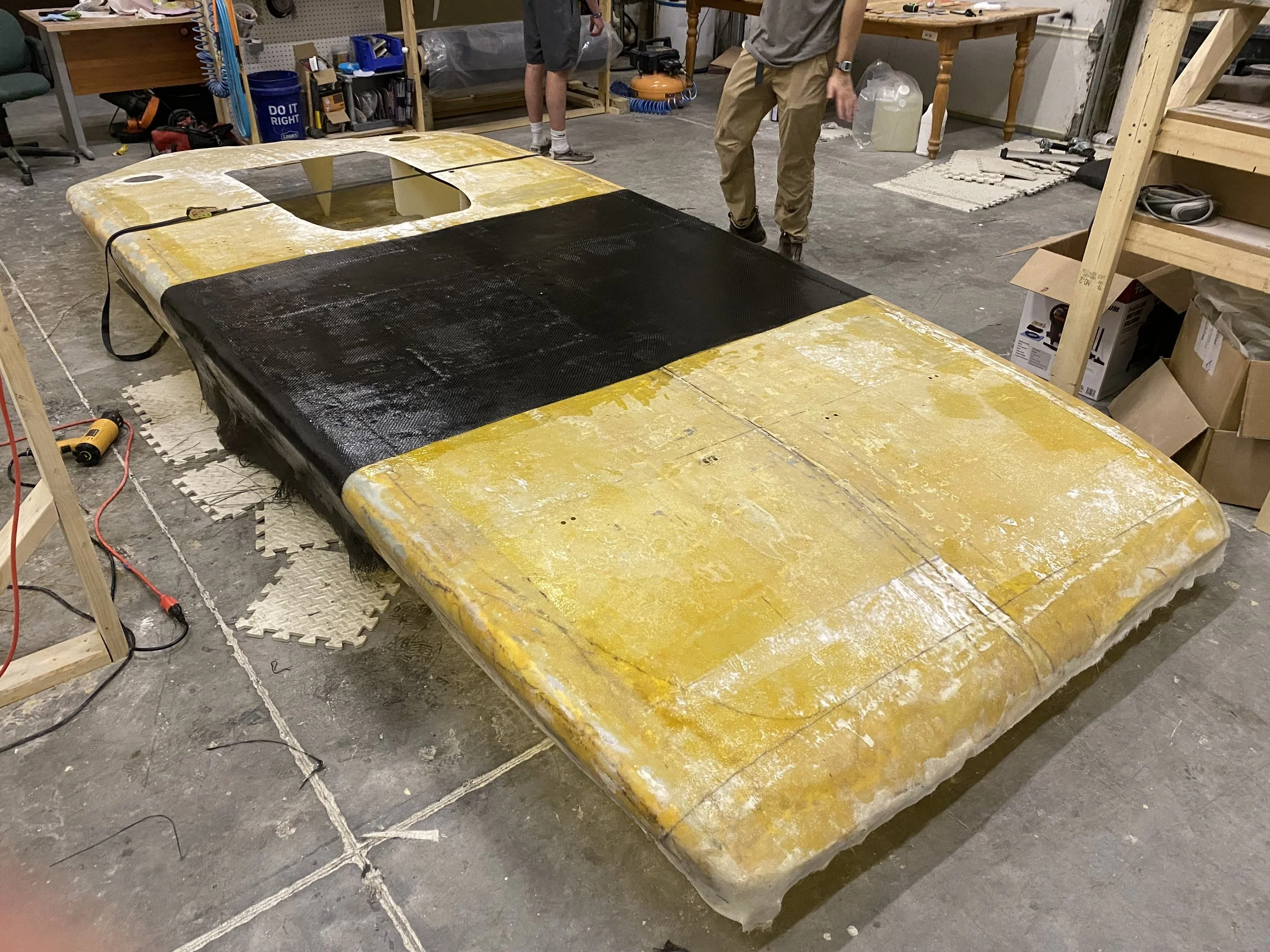

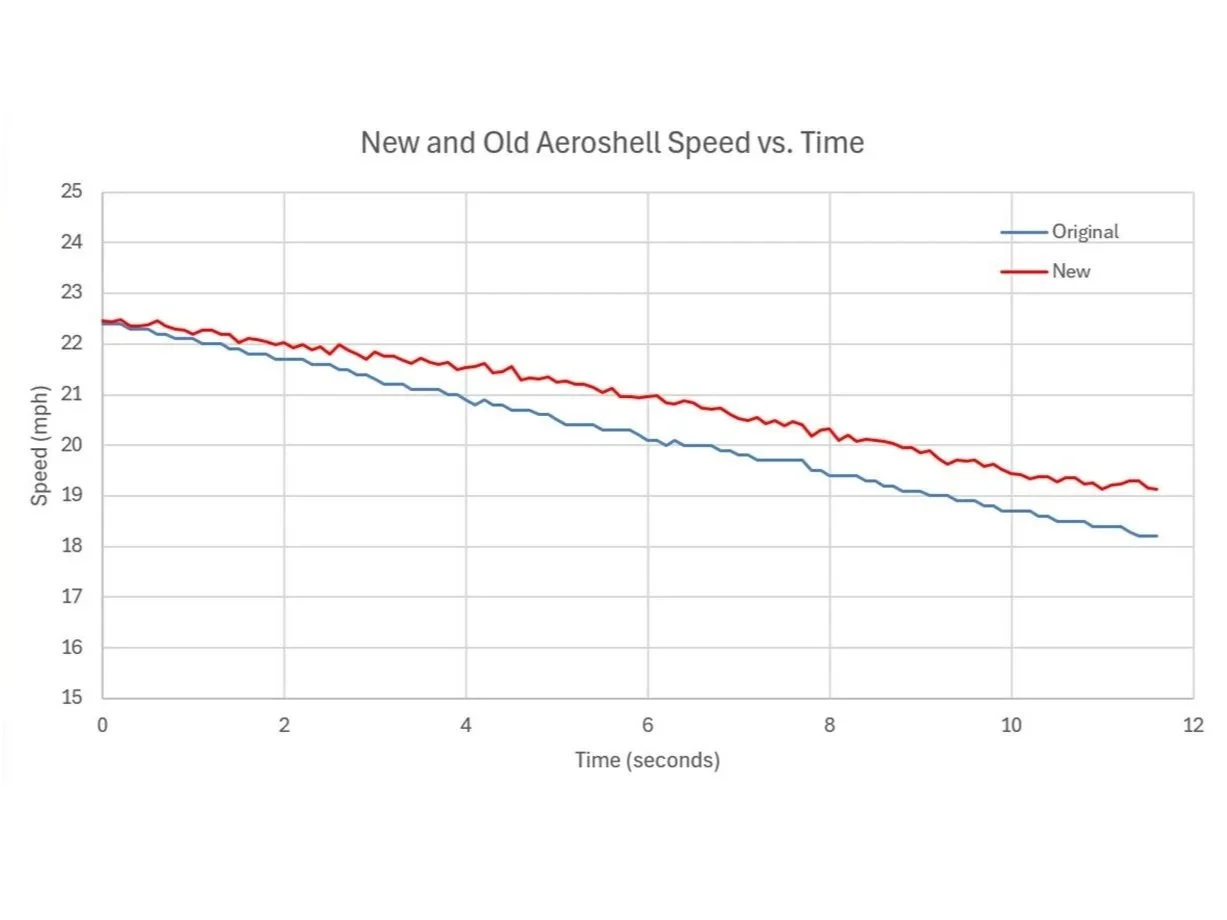

Aeroshell ManufacTURING

-

Challenge

• The solar car aeroshell exhibited surface roughness, gaps, and misalignment between the top and bottom halves, causing significant aerodynamic drag and unstable airflow

• The shell was structurally weak and flexible making it difficult to remove or reassemble without damage.

• These issues led to aerodynamic inefficiency during coast-down testing

-

Approach

• Undertook a remanufacturing process to rebuild the aeroshell using refined fiberglass layups and carbon fiber reinforcement to improve rigidity

• Focused on closing gaps between shell sections and ensuring smooth exterior surfaces for improved aerodynamic flow

• Prioritized durability and serviceability to make removal and maintenance of the aeroshell easier

-

Solution

• Successfully eliminated gaps and reduced surface imperfections

• The carbon-fiber-reinforced shell provided increased stiffness and improved handling during assembly and operation

• Coast-down testing confirmed a significant reduction in aerodynamic drag reflected by a measurable decrease in deceleration rate

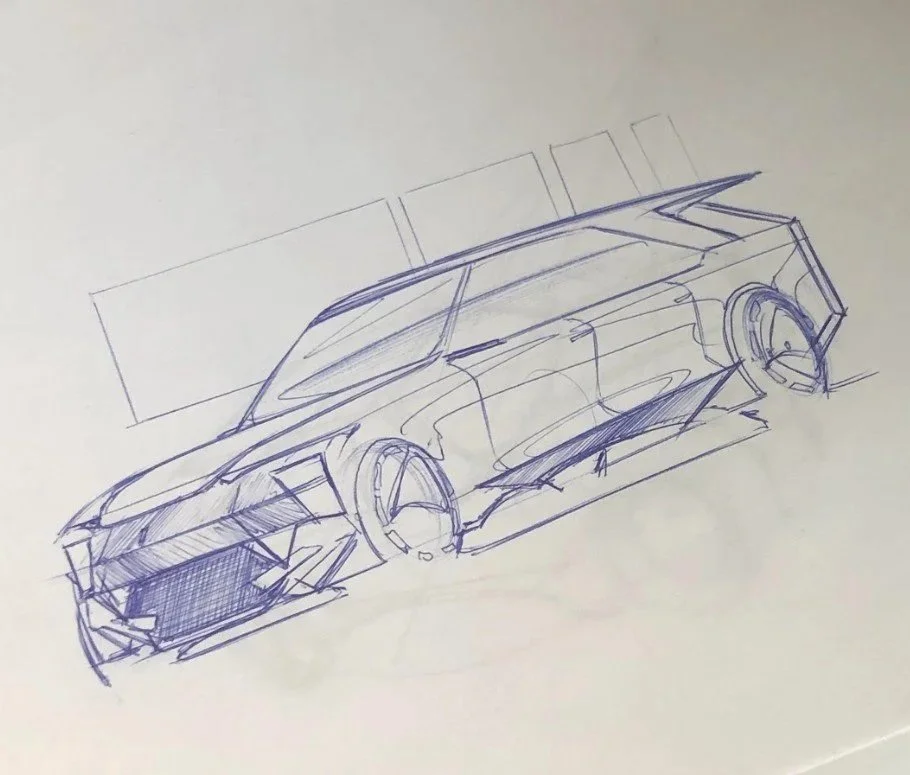

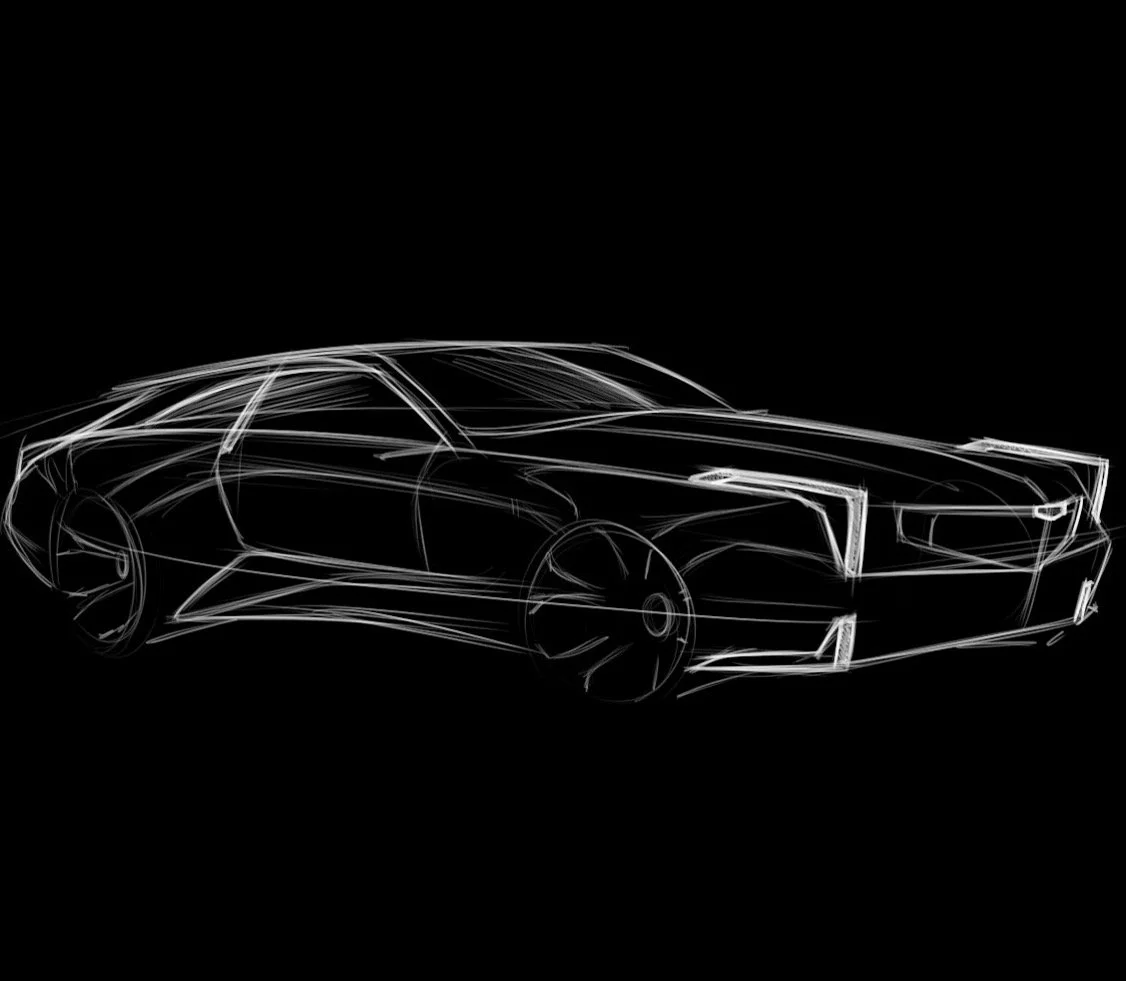

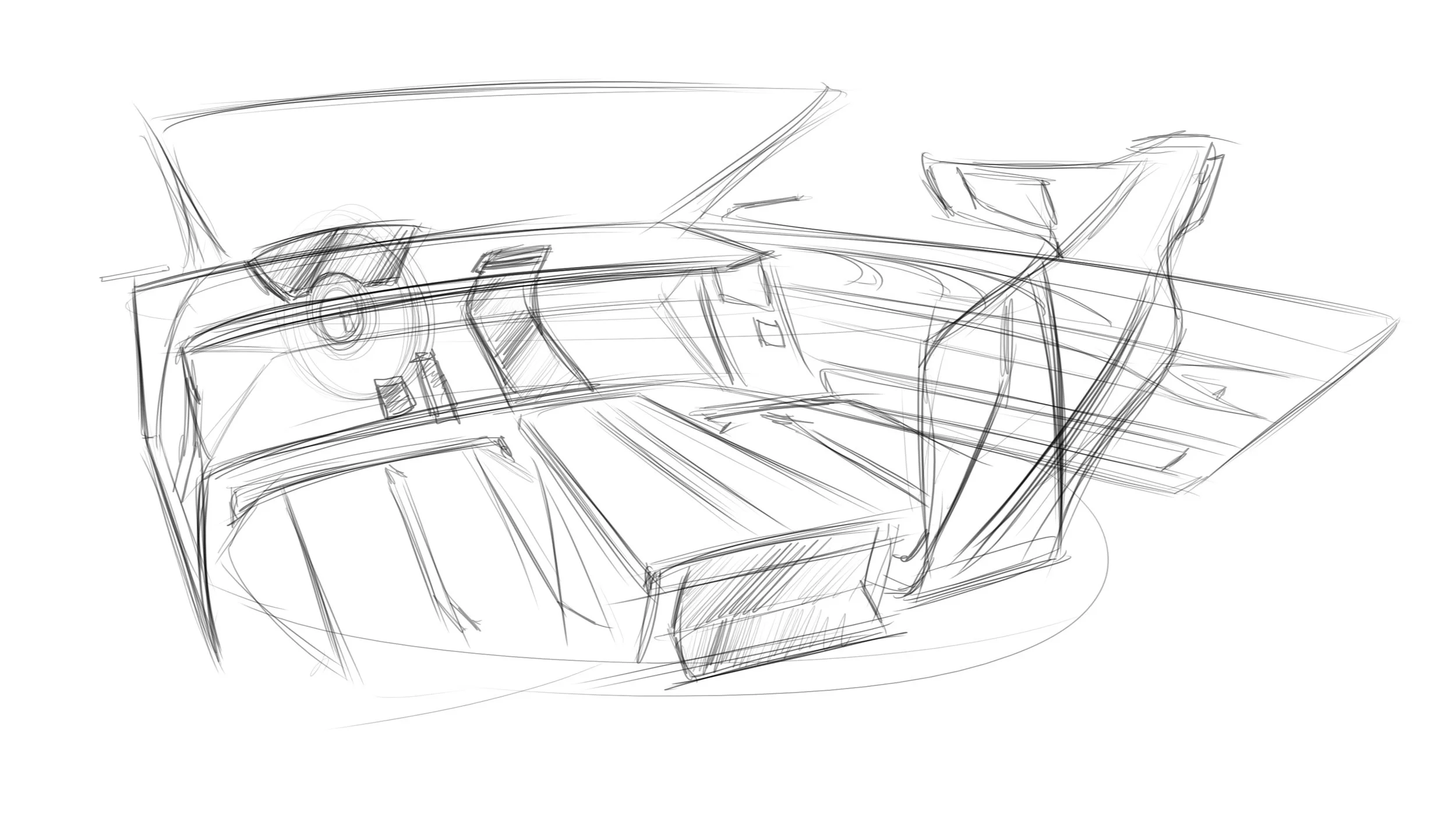

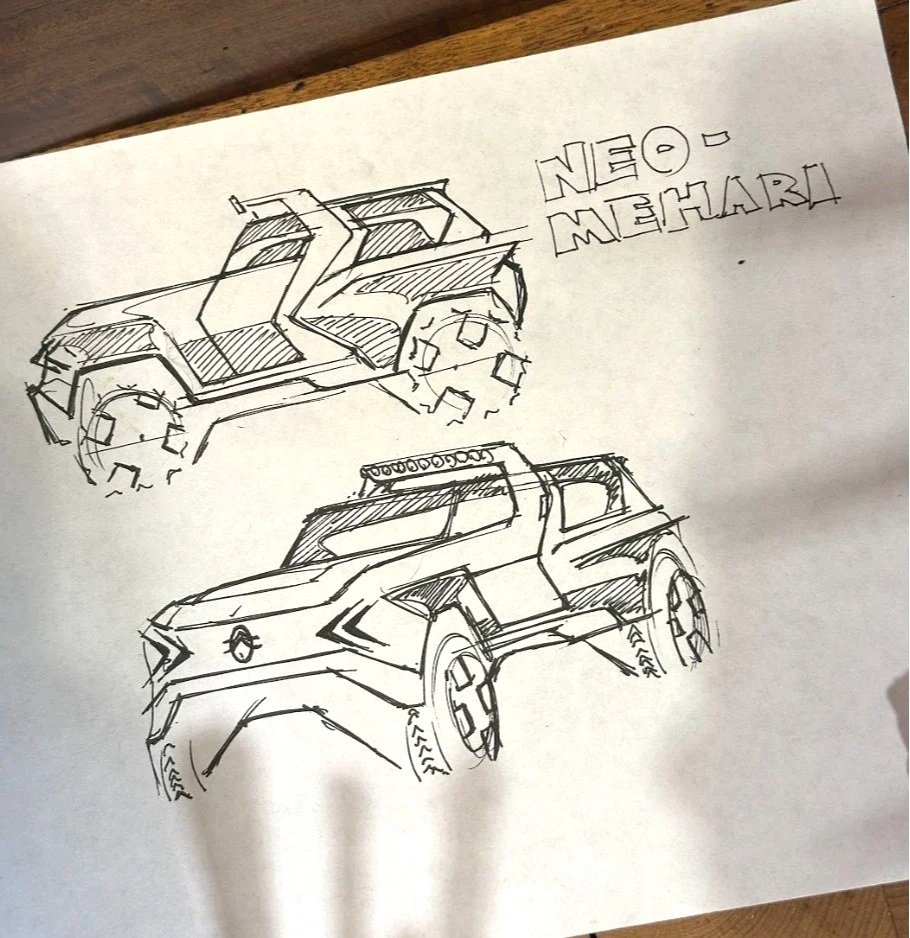

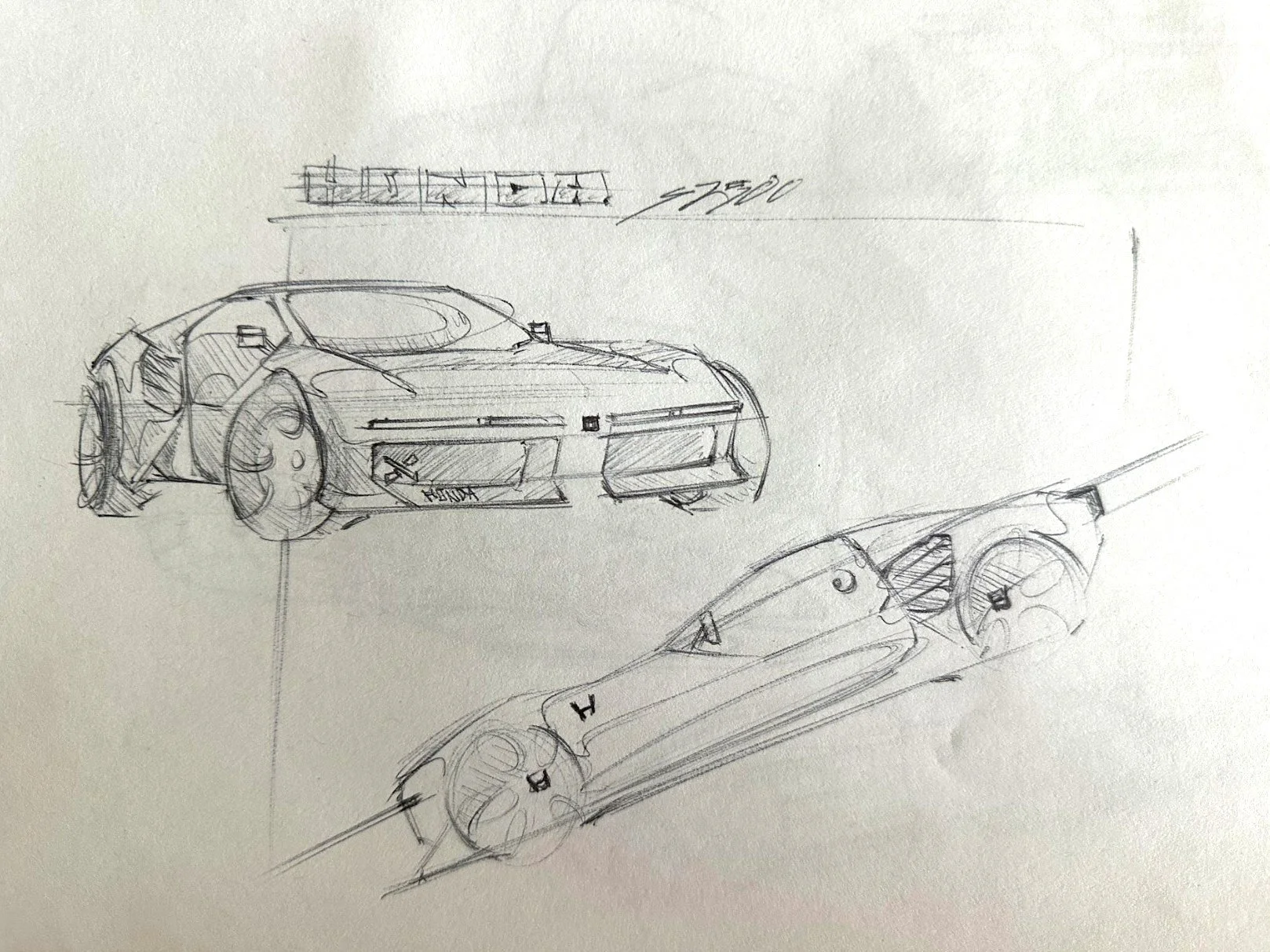

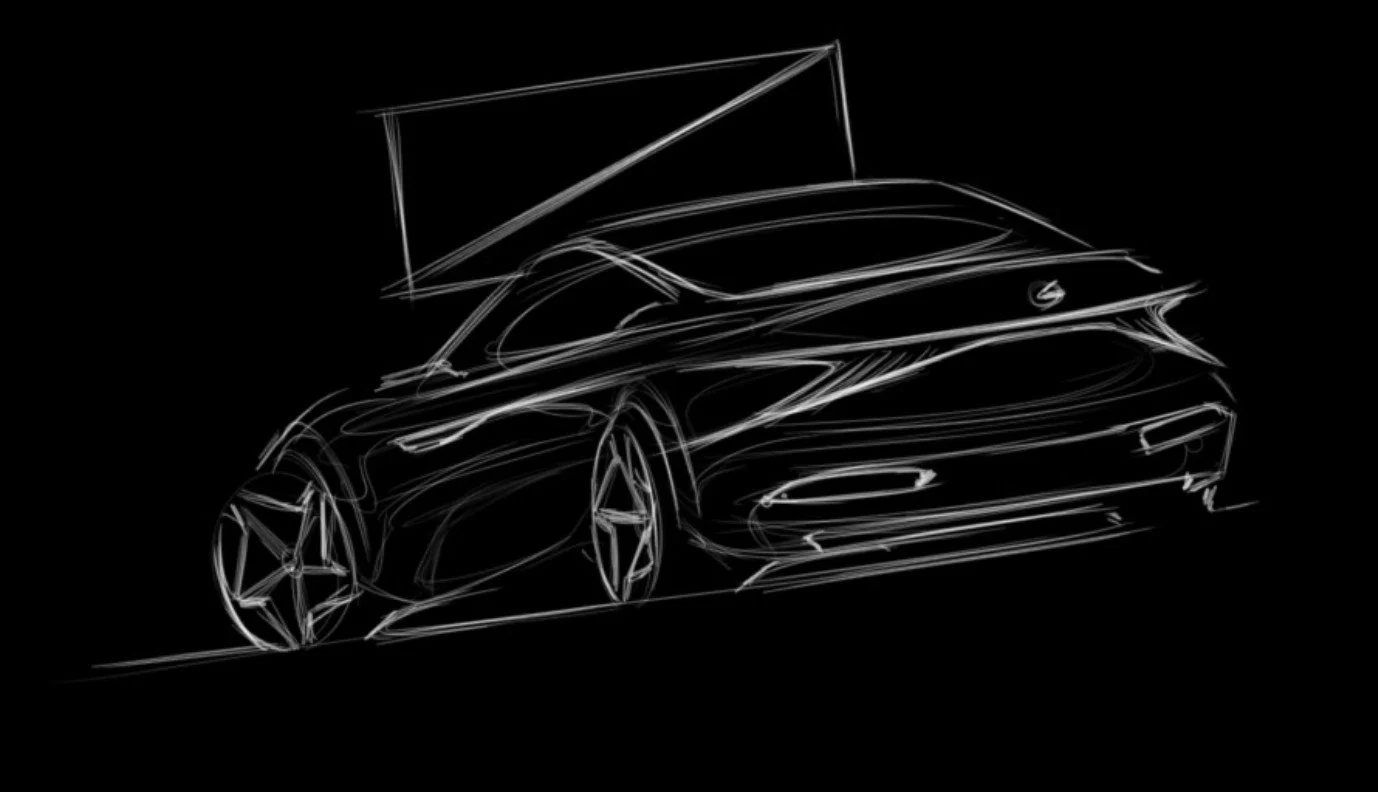

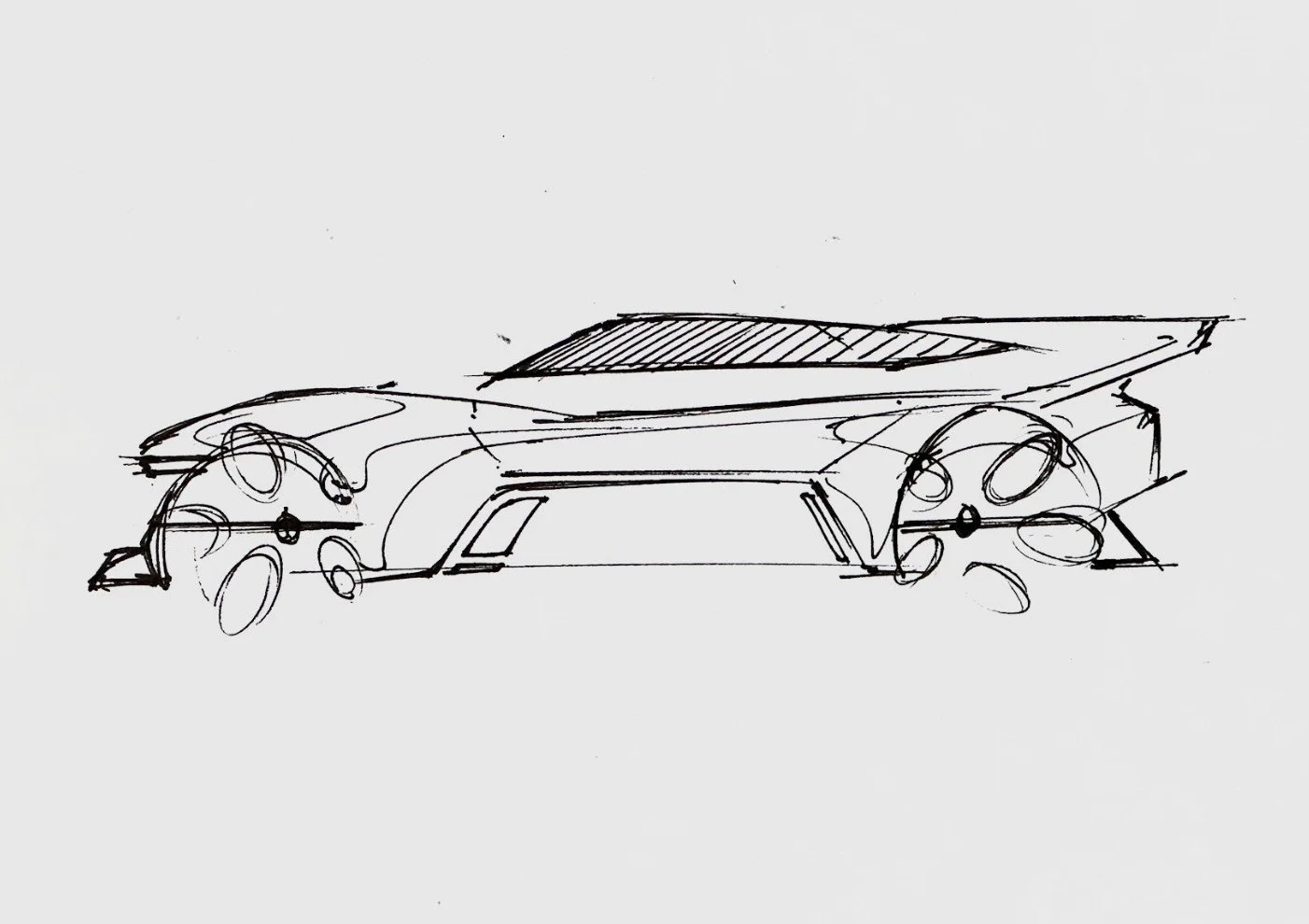

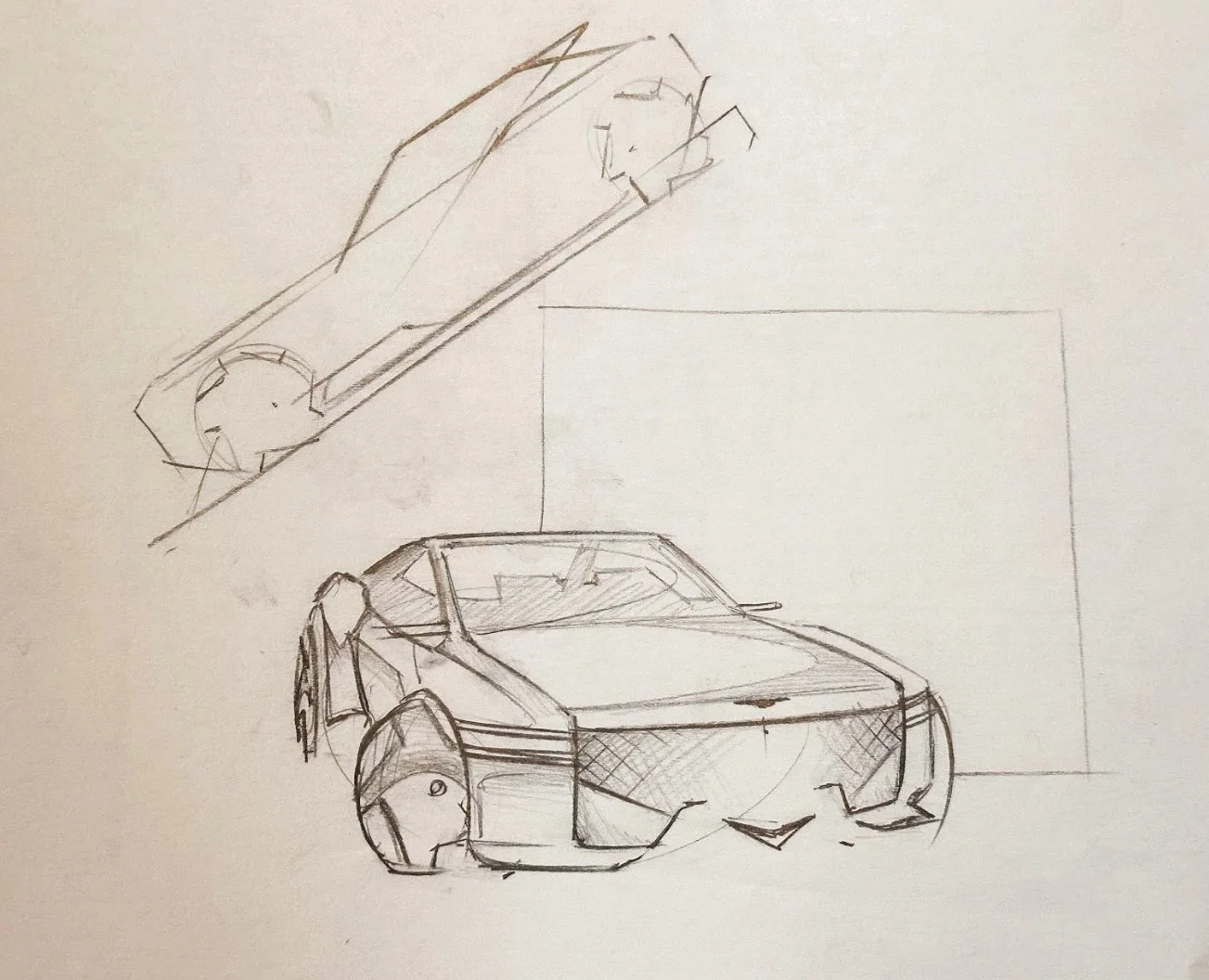

analog/digital automotive designs

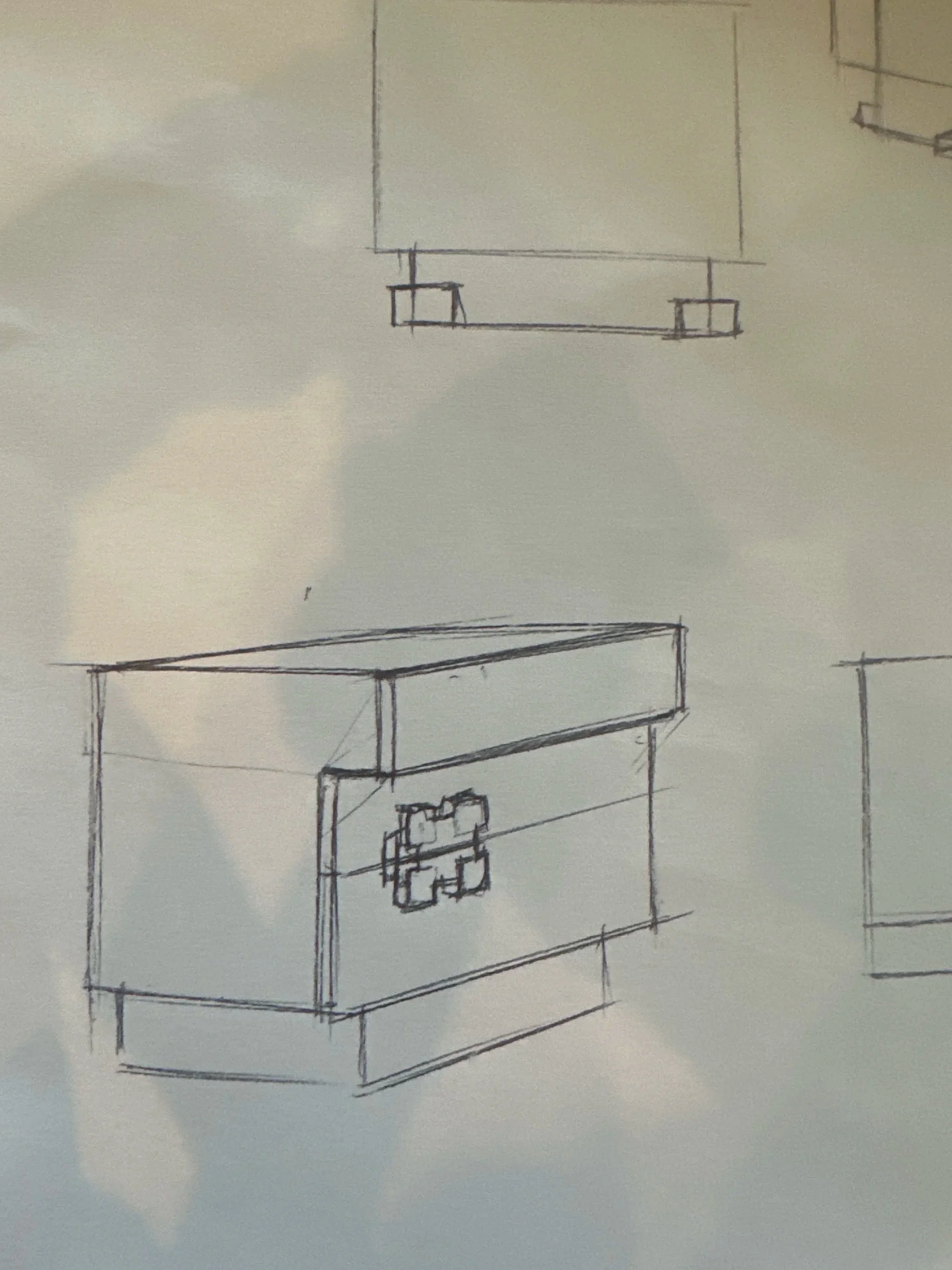

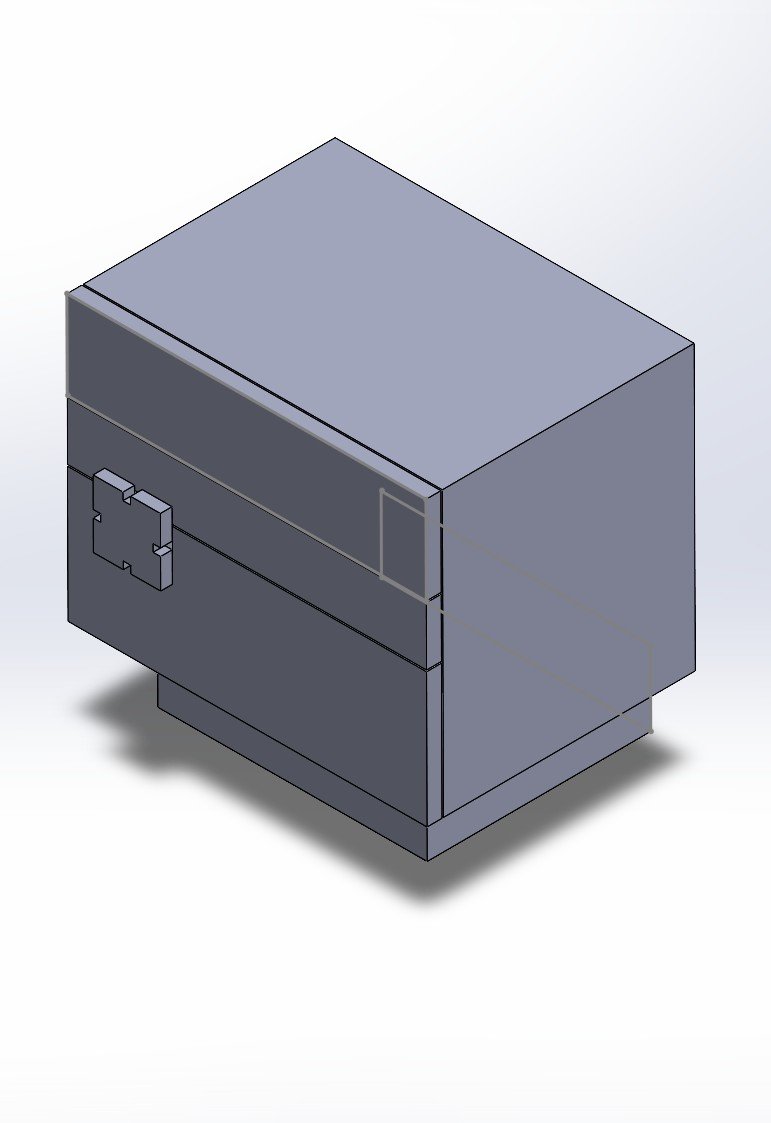

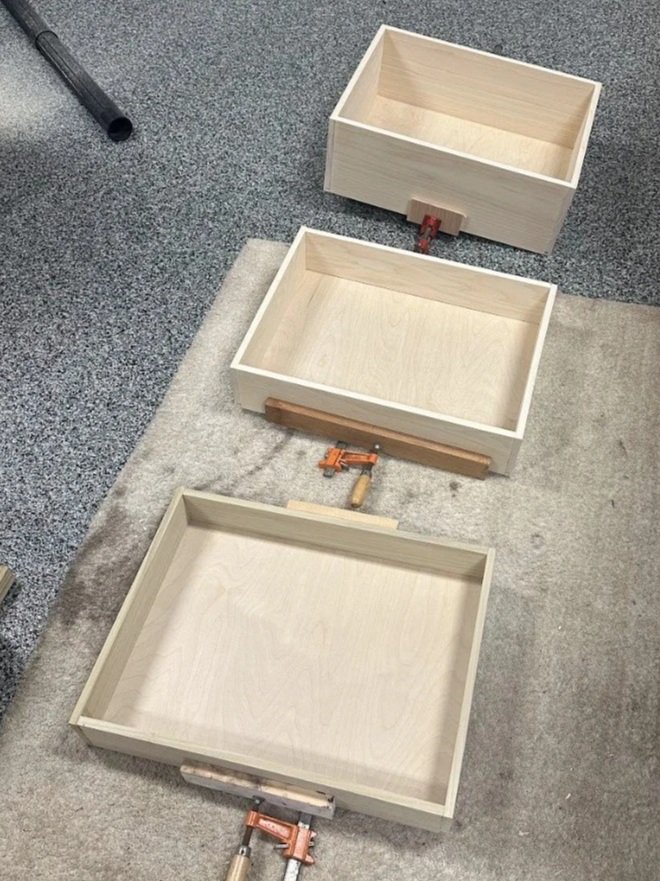

Brutalist Side Table

-

Challenge

• Create a mid-century modern/brutalist side table with solid woods and concrete

• Must feature 3 drawers—with the top drawer concealed to preserve brutalist look—and a large storage capacity

• All edges and seams must be precise and symmetrical

-

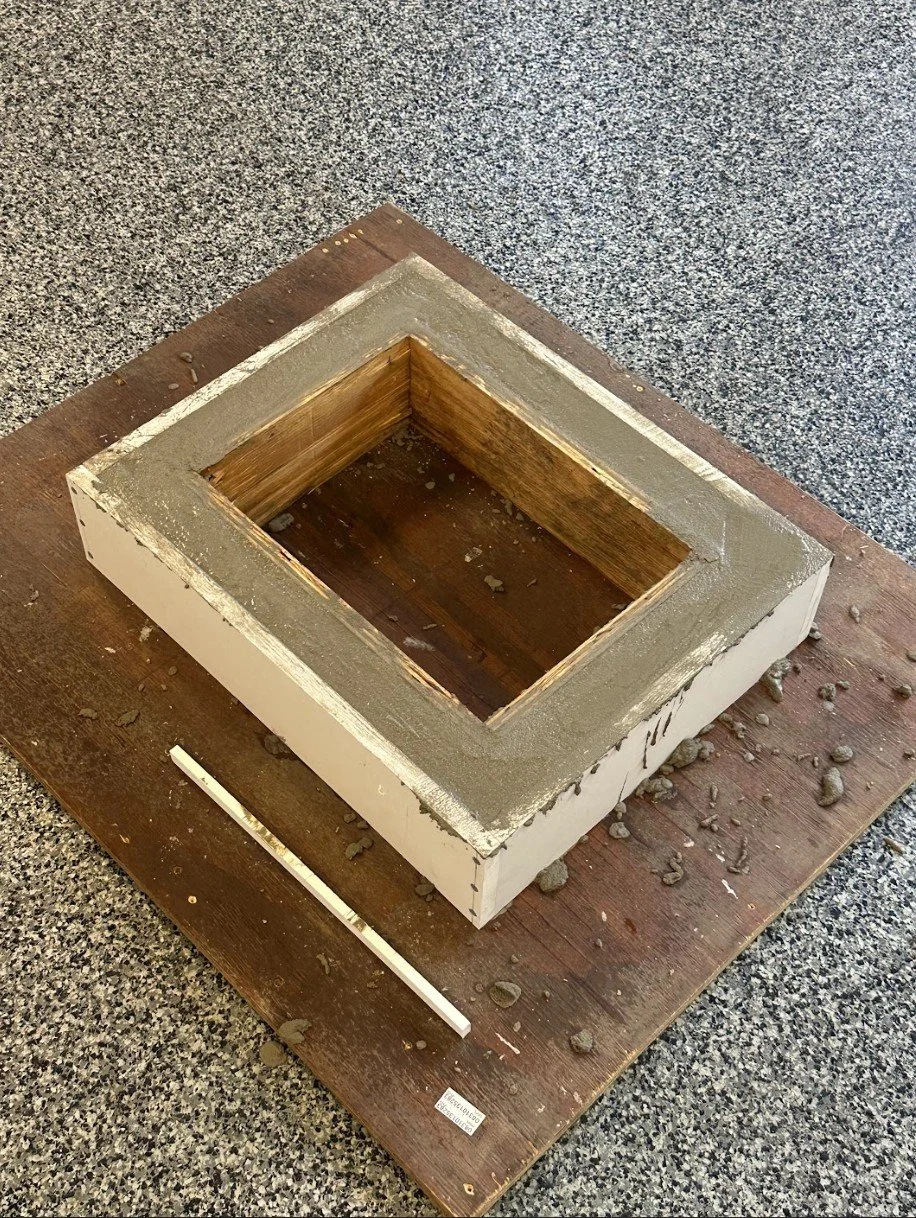

Approach

• Created a prototype in CAD to establish scaling and facade

• Used a miter saw, table saw, circular saw, and planar to cut solid white oak and pine

• Cut all of the top-drawer edges to 45 degrees to conceal it from all angles

• Created hollow concrete base molds: one with 90-degree interior corners and one with 45-degree corners for concrete crack resistance

-

Solution

• All drawers have soft close rails and line up flush between each other with a minimal gap

• The second iteration concrete mold displayed resistance to cracks

• Implementation of veneer oak on the back face saved weight to increase mobility